Developing for new intraocular lenses for cataract surgery

How research on lens properties helped improve cataract surgery procedures

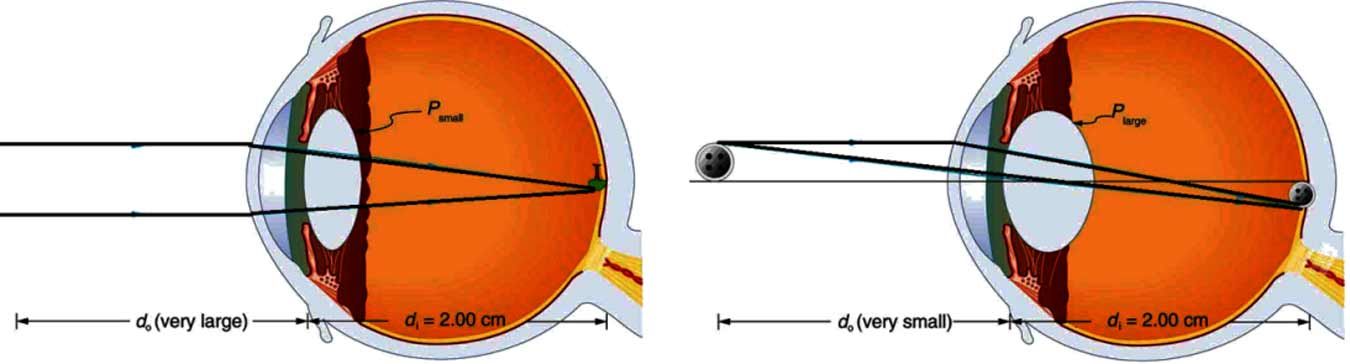

Since 2006, the Materials Research Group at Kingston University, led by Dr Baljit Thatti (Associate Professor), Dr Stephen Barton (Associate Professor) and Professor Peter Foot (Emeritus Professor), have been working on the characterisation and understanding of ophthalmic materials like lenses. The group's expertise in materials research led to a collaboration with Rayner Intraocular Lenses Ltd and its suppliers, to investigate and characterise surface interactions of intraocular lenses. The research group also successfully applied for a Knowledge Transfer Partnership Grant to study the behaviour of intraocular lenses (IOLs) by developing an in vitro model to better understand surface interactions with the eyes fluids and use this knowledge to engineer improved materials.

Incorporating the work done at Kingston University, as well as the team's simulated eye model, Rayner developed new models that were passed on to their IOL materials suppliers. They also provided procedural solutions to surgeons and patients involved in IOL implantation, ultimately protecting and improving the company's market share, reputation and sales.

Lower repeat trauma in patients

The team worked with the ophthalmic surgeon Romain De Cock to develop a new surgical implantation technique to help prolong the use of the intraocular lens within the eye. This measure has helped surgeons and patients by reducing complications of cataract surgery and ex-plantation rates of IOLs, thus leading to a lower repeat trauma in patients. This is an important feat, considering that repeat eye surgery has an enormous risk of damage, especially in elderly patients. This research has helped Rayner gain important knowledge, allowing the company to offer help to surgeons with complex cases and improving customers' trust in Rayner.

The company saw a subsequent 20% year-on-year growth in sales (including manufacturing and staff volume), meeting the company's aim of protecting continued sales growth. Rayner's R&D Director confirms: "It is unlikely that Rayner would have been able to complete this important research within the eventual timeframe of the project without the critical collaboration between the company, Kingston University and the KTP Associate." The contribution of Kingston researchers enhanced the value placed on research-driven knowledge within Rayner and allowed Rayner to invest heavily in their future product. This new R&D approach helped Rayner successfully launch a hydrophilic IOL product called RayOne in 2016, with excellent feedback from the market. This new product won the Queen's Award for Enterprise 2020 in Innovation. RayOne received FDA approval in 2018. To date, over 600,000 RayOne implantations outside of the US have taken place.

Safe and reliable

Since Rayner's supply chain includes various UK-based companies, the implant has also generated a secondary impact on the UK economy. The Chief Medical Officer of Central American Eye Clinics discussed the use of RayOne in America, Europe and El Salvador in his clinical review, concluding that the IOLs were safe and reliable, with excellent patient outcomes. Thus, the collaboration between Kingston University and Rayner opened up various new areas of product development for IOLs.

Contact us

- For non-student research enquiries, email the Research Office

- For research impact and REF enquiries, email the REF and Impact Team.

- Research contacts

- How to get to Kingston University